In the fast-paced world of the electronics industry, technology is constantly evolving. As with any industry, it’s crucial to not only stay ahead of the game but also ensure products have a long lifespan. This not only benefits the consumers but also helps build a solid reputation for our brand. In this article, we’ll discuss some valuable tips on how electronics manufacturers can ensure product longevity. Keep reading to discover a range of effective techniques to enhance the longevity of your electronics.

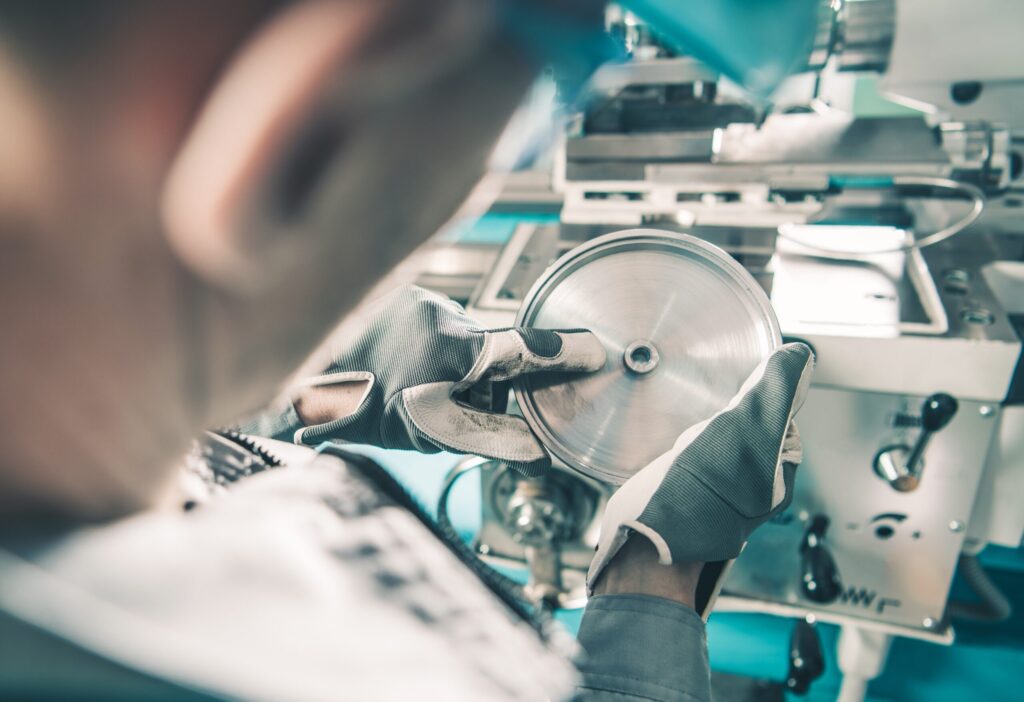

Choosing High-Quality Components and Materials

One significant way that electronics manufacturers can ensure product longevity is to choose high-quality components and materials. The choice of components and materials can significantly impact the overall performance and lifespan of electronic devices.

High-quality components are known for their durability, reliability, and suitability for specific applications. These components are designed and manufactured to meet stringent quality standards, ensuring they can handle the demands of the device they’re used in. By using such components, manufacturers can significantly reduce the risk of component failure, malfunction, or premature wear and tear, which can lead to costly repairs and replacements.

Similarly, the selection of high-quality materials plays a vital role in the longevity of electronic devices. These materials may include the casing, circuit boards, connectors, and various internal components. High-quality materials are typically more resilient to environmental factors such as temperature changes, humidity, and vibrations. They offer better resistance to corrosion, thermal expansion, and contraction, preventing damage to the device over time. High-quality materials can also mitigate the risks associated with electromagnetic interference, ensuring smoother operation and enhanced safety.

By prioritizing the use of high-quality components and materials, electronics manufacturers can enhance the overall quality and longevity of their products. This approach not only benefits the end-users by providing them with reliable and durable devices but also enables manufacturers to maintain a positive reputation, foster customer loyalty, and sustain their business in the competitive market.

Protecting Sensitive Components During the Shipping Process

Protecting sensitive components during the shipping process is essential for electronics manufacturers to ensure the longevity and performance of their products. With the advancements in technology, electronic devices are becoming increasingly intricate, making it vital to safeguard delicate components during transportation.

One effective method to protect these sensitive parts is by utilizing tools like plastic caps and plugs. These small yet versatile items are designed to fit precisely over various electronic components, sealing and protecting them from potential damage. Plastic end caps are frequently used to safeguard connectors, ports, and terminals, while plastic plugs are inserted into openings such as holes, tubing, or passageways, providing a secure barrier against foreign substances and impact.

By protecting sensitive components in the shipping process, manufacturers can minimize the risk of damage caused by accidental knocks, drops, or exposure to dirt and moisture. These protective tools act as a shielding layer, safeguarding the vulnerable components from any potential harm. Not to mention, caps and plugs also help prevent oxidation, which can corrode metal components and degrade their performance over time.

By investing in these protective tools, manufacturers can ensure products arrive at their destination in optimal condition, minimizing the risk of product failure and customer dissatisfaction.

Robust Product Design and Testing

Robust product design and testing is a crucial aspect of electronics manufacturing that can greatly contribute to the longevity and reliability of products.

When it comes to electronics, durability is of utmost importance, considering the harsh environments and conditions in which these products operate. Robust product design involves designing the product to withstand potential stressors, such as temperature variations, moisture, vibrations, and impacts. By designing products to withstand these stressors, manufacturers can ensure that the product performs optimally and lasts longer, reducing the need for repairs or replacements.

Thorough testing is another integral step in ensuring the robustness and reliability of electronic products. This involves subjecting the products to various tests, including temperature and humidity tests, drop and impact tests, and functional and performance tests. These tests help identify any weaknesses or vulnerabilities in the product design and allow manufacturers to make necessary improvements before mass production.

By investing in robust product design and testing, electronics manufacturers can create products that have a longer lifespan, better performance, and reduced potential for failure. This not only minimizes customer dissatisfaction but also saves costs associated with product recalls, warranty claims, and repairs.

Offering Regular Software Updates

Another effective strategy for electronics manufacturers to ensure product longevity is to offer regular software updates to end users. This practice benefits both the manufacturer and the consumers in several ways.

Firstly, regular software updates enable manufacturers to address any bugs or glitches that may have been overlooked during the initial release of the product. By constantly improving and optimizing the software, manufacturers can enhance the overall performance and functionality of the product. This ensures customers continue to have a smooth and efficient user experience, eliminating frustration with any technical issues that may arise.

Offering regular software updates also allows manufacturers to keep up with evolving technology trends and customer demands. As technology advances, new features and functionalities are continually being developed. Providing software updates gives manufacturers the opportunity to introduce these new features to existing products, keeping them competitive in the market and providing added value to customers. This can help extend the lifespan of the product, as customers may be more inclined to continue using a device that constantly evolves and offers new capabilities.

Moreover, regular software updates can address security vulnerabilities and protect users from potential threats. As cybercrime becomes increasingly sophisticated, manufacturers need to stay proactive in safeguarding their products. By regularly releasing security patches and software updates, manufacturers can ensure their devices remain secure and protected against known vulnerabilities. This not only enhances customer trust and satisfaction but also helps avoid potential damages resulting from security breaches.

By investing in ongoing software development, manufacturers can effectively extend the life of their products in the market, providing long-term value to their customers.

The Long-Term Benefits of Prioritizing Product Longevity

Now that we’ve covered some helpful strategies for ensuring product longevity, let’s take a closer look at the long-term benefits of this practice.

First and foremost, investing in product longevity improves customer satisfaction and loyalty. In today’s consumer-driven market, customers are seeking valuable and durable products that offer long-term usability. Satisfied customers are more likely to become repeat buyers and advocates for the brand, increasing sales and market share in the long run.

Prioritizing product longevity has economic benefits for manufacturers as well. Extending the life cycle of products reduces the need for frequent replacements, minimizing costs associated with research, design, production, and marketing. By focusing on creating more durable and repairable products, manufacturers can reduce warranty claims and the overall cost of customer support.

Furthermore, longevity gives manufacturers the opportunity to contribute to sustainability efforts. With environmental consciousness on the rise, consumers are increasingly concerned about the impact of their purchases. By extending the life of products, manufacturers can reduce waste and conserve resources. A focus on product longevity encourages a shift away from the disposable mindset, fostering a culture of conscious consumption.

From increased customer satisfaction and loyalty to economic advantages and sustainability contributions, focusing on durability and longevity can lead to a prosperous future for both manufacturers and consumers.

Overall, ensuring product longevity is of utmost importance for electronics manufacturers. By implementing strategies such as designing for durability, using high-quality components, and providing regular maintenance and updates, manufacturers can extend the lifespan of their products. This not only enhances customer satisfaction but also reduces environmental impact by minimizing electronic waste. By prioritizing product longevity, electronics manufacturers can establish themselves as leaders in the industry and contribute to a more sustainable future.